Difference between revisions of "Libero Manual"

m |

|||

| Line 1: | Line 1: | ||

this is an in-progress task.. pls do not edit. thanks! -- [[User:Red1|Red1]] 22:40, 19 December 2006 (EST) | this is an in-progress task.. pls do not edit. thanks! -- [[User:Red1|Red1]] 22:40, 19 December 2006 (EST) | ||

==User Manual== | ==User Manual== | ||

| − | A Manufacturing Resource is defined as anything required for production and | + | ===Manufacturing Rules=== |

| + | ===Manufacturing Resource Management=== | ||

| + | A Manufacturing Resource is defined as anything required for production and its unavailability can affect the Production Plan. Manufacturing Resources can be: Plants, Production lines, Work Centers and Work Stations. | ||

| − | It mainly | + | It mainly answers the question: Where is the product made? |

| − | === | + | ====Resource Type==== |

| − | The Resource Type Window is the | + | The Resource Type Window is the ADempiere standard option which it is used to calculate the available time in a resource. It allows input of ''starting time'' and ''end time'' for the slot according to the working days. For more information please look in the Reference Manual. |

[[Image:Libero1.png]] | [[Image:Libero1.png]] | ||

| Line 12: | Line 14: | ||

Figure 1.1.1.1 | Figure 1.1.1.1 | ||

| − | ===Manufacturing Resource | + | ====Manufacturing Resource==== |

To enter a Manufacturing Resource double-click in Manufacturing < Manufacturing Rules <Manufacturing Resource Management < Manufacturing Resource. | To enter a Manufacturing Resource double-click in Manufacturing < Manufacturing Rules <Manufacturing Resource Management < Manufacturing Resource. | ||

| Line 39: | Line 41: | ||

The available daily time will be calculated for every weekly working day selected, when you tick the Day Slot. The calculation to get the available time for a day substracts the time when the slot starts from the time when the slot ends. | The available daily time will be calculated for every weekly working day selected, when you tick the Day Slot. The calculation to get the available time for a day substracts the time when the slot starts from the time when the slot ends. | ||

| − | + | ===[[Manufacturing Workflows]]=== | |

| − | + | ||

| − | + | ||

| − | ===Manufacturing Workflows | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

===Data Planning==== | ===Data Planning==== | ||

====Planning Products==== | ====Planning Products==== | ||

Revision as of 11:59, 20 December 2006

this is an in-progress task.. pls do not edit. thanks! -- Red1 22:40, 19 December 2006 (EST)

Contents

- 1 User Manual

- 2 Cost Group

- 3 Create Cost Element

- 4 Create Element

- 5 Product Cost

- 6 Product Costing Report

- 7 Cost Collector

User Manual

Manufacturing Rules

Manufacturing Resource Management

A Manufacturing Resource is defined as anything required for production and its unavailability can affect the Production Plan. Manufacturing Resources can be: Plants, Production lines, Work Centers and Work Stations.

It mainly answers the question: Where is the product made?

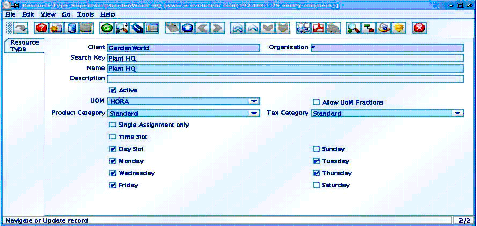

Resource Type

The Resource Type Window is the ADempiere standard option which it is used to calculate the available time in a resource. It allows input of starting time and end time for the slot according to the working days. For more information please look in the Reference Manual.

Figure 1.1.1.1

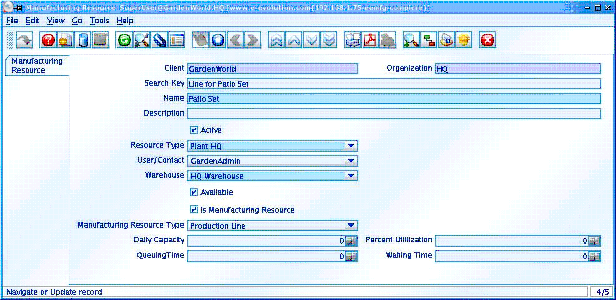

Manufacturing Resource

To enter a Manufacturing Resource double-click in Manufacturing < Manufacturing Rules <Manufacturing Resource Management < Manufacturing Resource.

The Manufacturing Resource defines a resource for an Organization. You can introduce as many resources as you wish.

Figure 1.1.1.2

The Resource Type field allows you to identify the capacity for this resource.

When you tick the Is Manufacturing Resource check box the next fields are shown: Manufacturing Resource Type, Daily Capacity, Percent Utilization, Queuing Time and Waiting Time.

In the Manufacturing Resource Type field you can select a Resource among Work station, Production Line, Work Center or Plant. Normally a group of work stations will be integrated into a work center, a group of work centers in a Production line and a group of production lines in a Plant. This relation is build in a hierarchy which is used to accumulate the required and available capacity since the lower to the upper hierarchies for each resource.

The Utilization Percent for a resource is defined as the required time for that resource divided by the available time, the result is multiplied by 100.

The Queue Time is the time which normally a manufacturing order operation has to wait since it is moved to this operation until it starts to be worked. The Waiting Time is the time which normally a manufacturing order operation has to wait since it is finished until it is moved to the next operation or to the warehouse. Both, queue time and waiting time entered in the resource are used as default values for the nodes in the workflow.

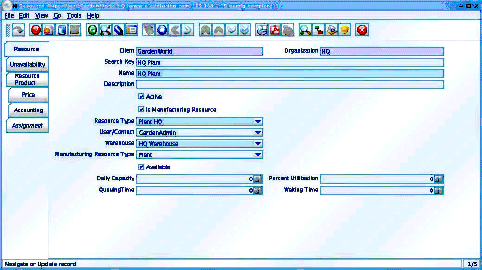

Figure 1.1.1.3

The Resource Window is opened with the menu option Partner Relations < Service <Resource, you can enter hollidays, the planned cost etc. as you need. For more information on Resource please refer to Compiere User Manual 252d Chapter 16. Service

The available daily time will be calculated for every weekly working day selected, when you tick the Day Slot. The calculation to get the available time for a day substracts the time when the slot starts from the time when the slot ends.